Recently,Shanghai Songjiang Vibration Absorber Group Co., Ltd. which excels in crafting expansion bellows and spring vibration isolators won the bid for the Shenlong Automobile Wuhan Plant project in 2013. The project utilized Shanghai Songjiang BE Rubber Vibration Isolator products, which have shown excellent performance in equipment vibration isolation in this project!

I. Brief Introduction of Shenlong Automobile Wuhan Plant:

Shenlong Automobile Co., Ltd. (hereinafter referred to as “Shenlong Company”) is an automobile production and operation enterprise jointly established by Dongfeng Motor Corporation and PSA Group from France. It was established on May 18, 1992, with its headquarters located in Wuhan, Hubei Province.

With three bases and five major factories, Shenlong Company is one of the first three major passenger car production bases planned and constructed according to economic scale in China. It has modern automobile production bases and research and development centers with complete functions and strong capabilities for independent research and innovation in Wuhan and Xiangyang. In Chengdu, the fourth factory is under construction and is expected to have an annual production capacity of 1 million vehicles by 2016.

Shenlong Company’s Xiangyang plant is a production base for powertrain components such as engines, transmissions, and axles. It currently has the production capacity of 1 million engines and 540,000 transmissions per year. The product range includes a series of new-generation engines such as the 1.6L CVVT, 1.8L CVVT, 1.6THP turbocharged direct injection, 1.8THP turbocharged direct injection, and 1.2THP turbocharged direct injection engines, which are internationally leading in technology and have excellent performance in terms of efficiency, economy, and environmental protection.

Shenlong Company’s Wuhan base has three major specialized factories with advanced equipment, process technology, and flexible production of multiple varieties. It currently has an annual production capacity of 600,000 vehicles. Wuhan Plant 1, which has an annual production capacity of over 300,000 vehicles, is praised as a “top flexible factory in China” focusing on the production of economical and intermediate passenger cars. Wuhan Plant 2, known as the “global benchmark factory of PSA Group,” is planned to have an annual production capacity of over 150,000 vehicles, focusing on the production of high-end passenger cars. Wuhan Plant 3, known as the “global new generation lean green benchmark factory,” produces economical to intermediate cars.

Shenlong Company’s Chengdu base started construction of the fourth factory on October 16, 2014. The total design capacity of Shenlong Company’s fourth factory is 360,000 vehicles per year, with production scheduled to start by the end of 2016. It mainly produces vehicles under the Dongfeng Citroën, Dongfeng Peugeot, and Dongfeng brands, with a focus on high-end SUVs and MPVs, as well as planning for new energy products.

II. Shenlong Automobile Wuhan Plant: One Company, Two Brands:

Shenlong Company implements the operational management mode of “one company, two brands,” with its marketing headquarters located in Wuhan and the brand departments of Dongfeng Citroën and Dongfeng Peugeot located in Shanghai and Beijing, respectively. Dongfeng Citroën brand advocates “human-oriented technology, creating and enjoying life” as its core value, currently offering product series including C5, C4L, Sega, new Elysee, C3-XR, etc. Dongfeng Peugeot brand adheres to the brand concept of “moving forward together, innovating for the future,” and currently offers product series including 508, 408, 3008, 308, 301, 2008, covering high-end, mid-to-high-end, economical, and SUV segments of the passenger car market.

Shenlong Company’s two brands have established over 1,000 4S dealerships nationwide and implemented diversified dealership development models such as 4S, 3S, and 2S+A, expanding into second and third-tier cities and county markets, faithfully providing satisfactory services to more than 4 million customers.

III. Shenlong Automobile Wuhan Plant: Independent Innovation, Soaring High:

Shenlong Company insists on enhancing its product technology research and development innovation capabilities as an important strategic support for enhancing its core competitiveness. Currently, Shenlong Company has laboratories for vehicle, engine, components, materials, environment, and in-car air quality, as well as high-standard vehicle test grounds.

Through the in-depth implementation of the “Kunpeng Plan” aimed at enhancing independent research and development capabilities, Shenlong Company’s scientific and technological talent team has further strengthened, currently with over 1,600 R&D personnel. Technological capabilities have also been improved, with the ability to co-develop new models, independently modify models, and completely independently develop annual models. More and more products are infused with the “Shenlong gene” and “Chinese elements.”

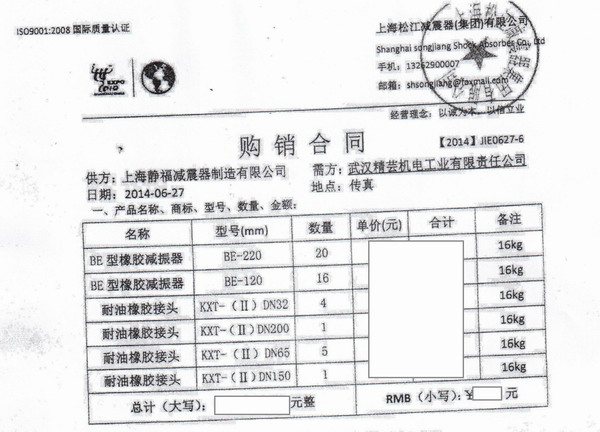

Below is the authentic photo of songjiang rubber vibration isolators.

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In the comprehensive evaluation of technological innovation in the Dongfeng Group’s research and development system, Shenlong Company has ranked first for eight consecutive years and has won over 100 awards for technological progress, including the “China Automobile Industry Science and Technology Progress First Prize.” As a national-level technology research and development center, Shenlong Company’s technical center has also been awarded the title of “Advanced Collective of Central Enterprises.

Related links:BE type Rubber Vibration Isolator