【China National Materials International ABMC 10,000 Tons Per Day Cement Production Line Project】Shanghai Songjiang Rubber Expansion Bellows

Shanghai Songjiang Vibration Isolator Group Co., Ltd. provided Shanghai Songjiang rubber expansion bellows products for China National Materials International Engineering Co., Ltd. on the ABMC 10,000 Tons Per Day Cement Production Line Project on August 8, 2014.

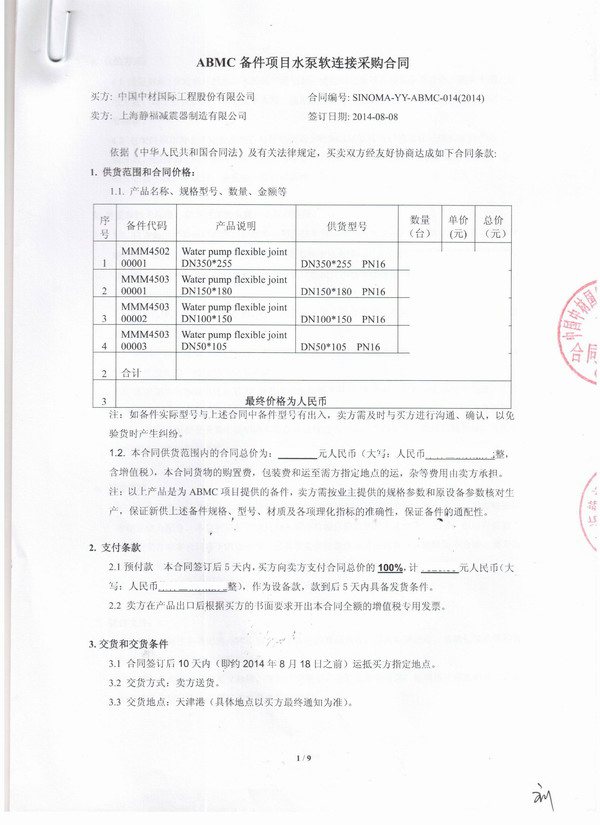

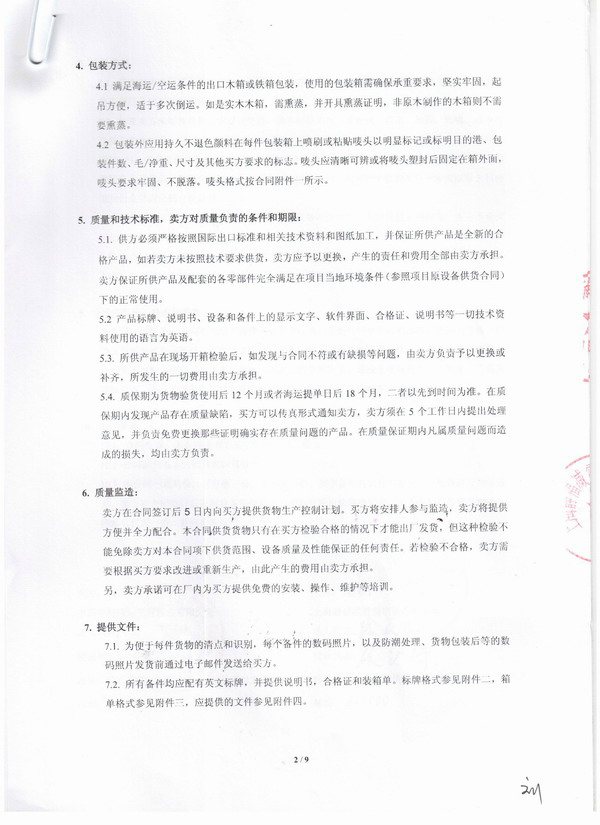

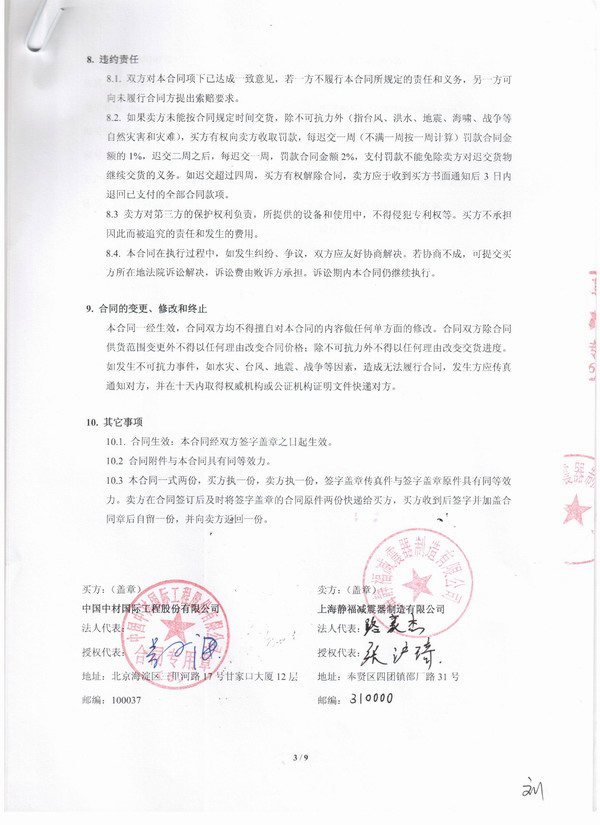

I. Scanned copy of the contract for the use of Shanghai Songjiang rubber expansion bellows in the China National Materials International ABMC 10,000 Tons Per Day Cement Production Line Project:

II. Introduction of the contract for the use of Shanghai Songjiang rubber expansion bellows in the China National Materials International ABMC 10,000 Tons Per Day Cement Production Line Project:

Shanghai Songjiang Vibration Isolator Group Co., Ltd. provided Shanghai Songjiang rubber expansion bellows products for China National Materials International Engineering Co., Ltd. on the ABMC cement plant project in the UAE on August 8, 2014.

Product Brand: Songjiang

Production Address: No. 699 Caosheng Road, Jiading District, Shanghai

Manufacturer: Shanghai Songjiang Vibration Isolator Group Co., Ltd.

III. Basic Information of DN250 Single Sphere Rubber Expansion Bellows Used in China National Materials International ABMC 10,000 Tons Per Day Cement Production Line Project:

Product Alias: Flexible Rubber Joint, Rubber Flexible Connector, Vibration Isolator, Flange Flexible Connector, Rubber Flexible Joint, Rubber Pipe Joint, etc.

Product Specification: DN250mm

Product Pressure: 0.6-2.5MPa

Vibration Reduction Grade: Grade A, excellent vibration reduction performance

Product Certification: ISO9001-2008

Applicable Scope: Acid, alkali, corrosive, oil, hot water, cold water, compressed air, compressed natural gas, etc.

Product Material: Environmentally friendly high-quality natural synthetic rubber, environmentally friendly and pollution-free, free of lead and other toxic substances.

Product Color: Black, actual color see product display pictures.

Working Temperature: -40 degrees to 80 degrees (can also be processed with high temperature resistant rubber expansion bellows)

IV. Ordering Notes for DN250 Single Sphere Rubber Expansion Bellows:

If the customer has special requirements for the product, the following instructions should be provided in the ordering contract: (1) structural length, (2) connection form, (3) nominal diameter, full diameter, reducing diameter, pipe size, (4) medium and temperature, pressure range, (5) experimental, inspection standards and other requirements. The factory can customize and design special products according to the special requirements of customers.

The factory can customize and design special products according to the special requirements of customers.

If the customer provides the determined product type and model, the customer should correctly explain the meaning and requirements of its model, and sign the contract under the condition that the supply and demand parties understand each other.

V. Advantages of DN250 Single Sphere Rubber Expansion Bellows Contract Used in China National Materials International ABMC 10,000 Tons Per Day Cement Production Line Project:

Reduce vibration, reduce noise, good flexibility, easy to use.

Small size, light weight, good elasticity, easy installation and maintenance.

When installed, it can produce lateral, axial, and angular displacement, not limited by pipeline eccentricity and flange non-parallelism.

It can reduce structural transmission noise during operation, with strong vibration absorption capacity.

Due to the excellent comprehensive performance of rubber expansion bellows, it is widely used in chemical industry, construction, water supply, drainage, petroleum, light and heavy industries, refrigeration, sanitation, plumbing, fire protection, power and other basic engineering. It is especially suitable for pipelines with large vibration and frequent thermal and cold changes.

VI. Introduction of China National Materials International ABMC 10,000 Tons Per Day Cement Production Line Project:

The ABMC 10,000 Tons Per Day Cement Production Line Project is developed by the Abu Dhabi ARKAN Building Materials Group and contracted by China National Materials International Overseas Business Development Company (formerly China Building Materials Equipment Co., Ltd.) as the EPC turnkey project. The project was signed on March 19, 2006, with a contract amount of $276,313,000. Construction started on September 16, 2007, equipment installation was completed in September 2009, single equipment commissioning was conducted using diesel generators provided by the owner in October 2009, and material crushing and pre-homogenization sub-item feeding commissioning began in April 2011. On November 7, 2012, ignition was successfully achieved, and material was successfully produced on November 12. Currently, the project is striving towards material feeding commissioning, performance testing, and comprehensive handover.

Against the backdrop of friendly cooperation and strategic reciprocity with the owner, our company successfully signed an operation and production maintenance contract with the owner for a period of 19 months with 320 personnel in April 2010, with a total amount of $21,000,000. The contract was repeatedly delayed due to the owner’s lack of raw materials and fuel, and finally officially started on July 11, 2012. Currently, the total number of personnel in the plant has reached 302, and the factory has begun to sell materials and cement externally.

VII. Introduction to ABMC Cement Plant Project in the UAE: (Information below is from the internet)

Overseas companies organized a careful and comprehensive safety production inspection of the three major workshops, two key departments, quality testing and control center, central control room, and electrical rooms of the ABMC project site. This inspection strictly followed the instructions of China National Materials Group and China National Materials International on the safety production work during the Mid-Autumn Festival and National Day, and in accordance with the deployment and requirements of the company’s safety and quality management office, focusing on various hazards, high-risk and confined space operation processes, “three violations” phenomena and management measures, chemical safety management, fire facilities and fire equipment, electrical facilities, environmental sanitation of living and camp areas, etc.

Subsequently, a summary meeting of the safety inspection was held on site. Chief Engineer Chen Baohua fully affirmed the seven-year safe and stable production of the ABMC project since its commencement of operation and the issuance of PAC. Regarding the eight problems found in this inspection, such as the lack of isolation facilities at the temporary work site of the frequency converter, he demanded strict implementation of rectification in accordance with the spirit of China National Materials Group and China National Materials International documents and the principle of “five determinations” (determining measures, determining funds, determining responsible persons, determining time, determining contingency plans), and timely reporting to the company. Chen Baohua emphasized: inspection is not the purpose, it aims to strengthen personnel safety awareness, “red line” awareness, and strengthen the construction of “three systems”, to achieve personnel safety, equipment safety, and production safety, happily go abroad, and safely return home.

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

Finally, he requested further inspections by workshops and departments on site, immediate rectification of problems found, and implementation at all levels to ensure safe and stable production, and strive for the renewal of operation contracts when they expire. Deputy General Manager Bu Jianjun reported and introduced the construction situation of overseas company projects and the execution of ABMC project construction contracts and production operation contracts to Ambassador Chang Hua. He emphasized that the ABMC project has experienced twists and turns over nine years, experienced long-term suspension, but with the strong support of the ambassador and counselor, and the hard work of the company, the project has achieved great success. On February 27, 2014, PAC was obtained, and negotiations for FAC issuance and production operation renewal are currently underway. Throughout the process, whether it is project construction or production operation, it has been fully affirmed and recognized by the owner. Ambassador Chang Hua listened attentively to the on-site report, and inquired in detail about the situation of Chinese engineering and technical personnel and workers. On behalf of the Party Committee of the Chinese Embassy in the UAE, he expressed warm condolences to all Chinese management personnel and workers at the overseas company’s ABMC project site, and fully affirmed the positive role played by the overseas company’s ABMC project in promoting economic and trade relations between China and the UAE.

Through the continuous efforts of Chinese enterprises, a market has been opened in the UAE, and our technological capabilities and levels have been recognized locally. It is hoped that through our advanced technology and continuous efforts, we can expand and strengthen ourselves on the one hand, and protect the environment on the other hand. This will play a good demonstration role in vigorously promoting the construction of the “Belt and Road” by the Chinese government and transferring domestic enterprise capacity. Ambassador Chang expressed that the completion and operation of the ABMC project is a symbol of cooperation between China and the UAE, and it must be maintained and operated well, which is of great significance for further strengthening the future cooperation between the two countries. Ambassador Chang finally said that the local climate in the UAE is poor, with high summer temperatures, and hopes that the management will pay more attention to the workers’ lives, especially to production safety, strengthen labor protection for workers, make them happy to come and go safely, and wish everyone safe work and good health.

Related links:Rubber Expansion Bellow with tie rod For Water pipes From Leading Brand Rubber Expansion Bellow Manufacturer