In the bustling automotive industry, ensuring efficient production processes while maintaining optimal working conditions is paramount. Geely Powertrain Yiwu Factory exemplifies this commitment by incorporating state-of-the-art solutions like Songjiang Expansion Bellows into their operations.

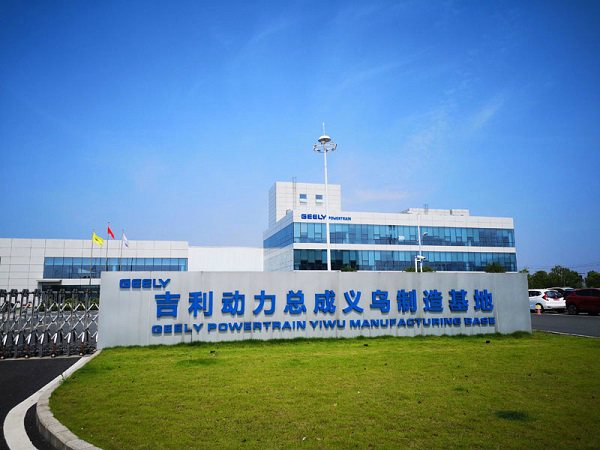

Introduction to Geely Powertrain Yiwu Factory:

Geely Powertrain Yiwu Factory stands as a testament to Geely Group’s dedication to innovation and excellence. Situated in the heart of Nanqingkou Automobile Industry Park, Zhejiang Province, this facility embodies the integration of advanced manufacturing with sustainable practices. Comprising multiple manufacturing units including Zhejiang Fengrui Engine Co., Ltd. and Yiwu Geely Engine Co., Ltd., this high-tech enterprise specializes in engine research, development, and production. With a focus on quality and efficiency, the factory has witnessed remarkable milestones since its inception, contributing significantly to Geely’s renowned lineup of vehicles.

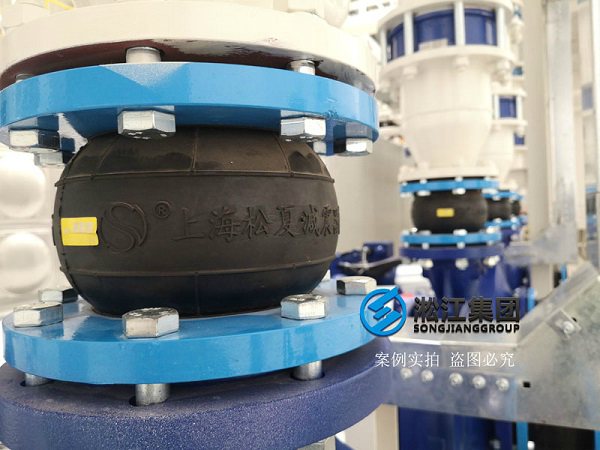

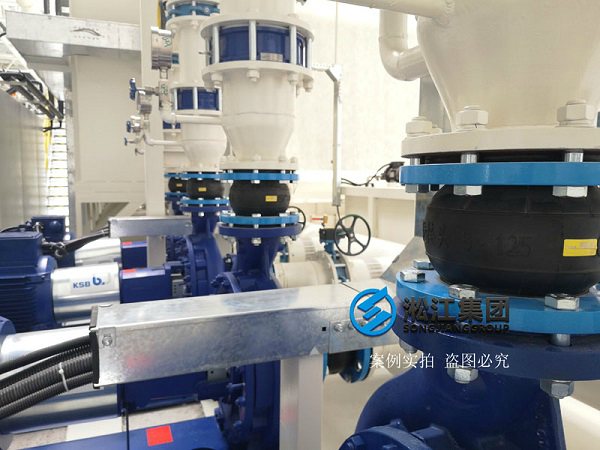

Installation of Songjiang Rubber Expansion Bellows:

In the quest for operational excellence, Geely Powertrain Yiwu Factory recognized the need for reliable solutions to enhance the efficiency of its machining fluid workshop. This led to the adoption of Songjiang Rubber Expansion Bellows, renowned for their superior quality and durability. These expansion bellows play a crucial role in maintaining the integrity of fluid systems, facilitating seamless movement while effectively mitigating vibrations and fluctuations. The installation process at the machining fluid workshop showcased meticulous attention to detail, ensuring optimal performance and longevity.

Requirements for Rubber Expansion Bellows in Machining Fluid Workshop:

The machining fluid workshop, being a critical component of the production process, imposes specific requirements on the rubber expansion bellows utilized:

Corrosion Resistance: Given the presence of various chemicals in machining fluids, the expansion joints must exhibit exceptional corrosion resistance to withstand harsh environments and ensure longevity.

High-Temperature Stability: Operating in environments with elevated temperatures demands rubber expansion joints capable of withstanding heat without compromising performance or structural integrity.

Pressure Endurance: The fluctuating pressures associated with machining fluids necessitate expansion joints that can withstand varying levels of pressure to prevent leaks and maintain system efficiency.

Flexibility: Optimal functionality in dynamic environments requires expansion joints with superior flexibility, enabling seamless movement and accommodating changes in system dynamics.

Sealing Performance: Effective sealing capabilities are essential to prevent fluid leaks and maintain a clean, safe working environment within the workshop.

Below is the authentic photos of Songjiang rubber bellows installation. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In conclusion,the successful integration of Songjiang Rubber Expansion Bellows into the machining fluid workshop at Geely Powertrain Yiwu Factory underscores the commitment to excellence and innovation within the automotive industry. By prioritizing quality, durability, and performance, Geely continues to set new benchmarks in manufacturing efficiency and operational reliability, ensuring a sustainable future for automotive production.

Related links:Vibration Reduction KXT Rubber Expansion Bellow with Flanges From Leading Brand Rubber Expansion Bellow Manufacturer