100% virgin material EPDM rubber expansion bellows installation suggestion

Rubber Expansion Bellow Manufacturer-Shanghai Songjiang Group Introduce to Everyone:100% virgin material EPDM rubber expansion bellows installation suggestion

Key factors for installation

The following advice is however to be taken into consideration to obtain good performance and prolong the expansion joint.

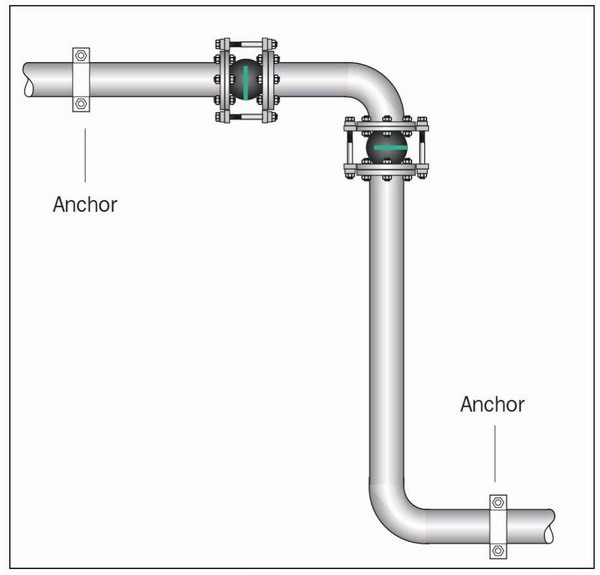

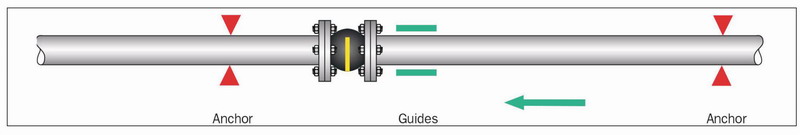

Fixed points

An expansion joint acts as a piston by the forces arising from the internal pressure. To prevent the pipes from damage they are to be properly anchored to take care of these reaction forces (Fr).

The Reaction force of an expansion joint is calculated by the following formula:

Fr = Q x P x 0.01

Fr = reaction force in kN.

Q = effective cross-sectional area in cm2.

P = actual pressure in bar or KP/cm2

Installation

The turnable metal flanges make installation easier and eliminate twists.

The low inherent rigidity of Sungkiang expansion joints makes for easier accommodation of installation dimensions.

Check the permissible movements, temperature, pressure, and proper rubber quality before installation!

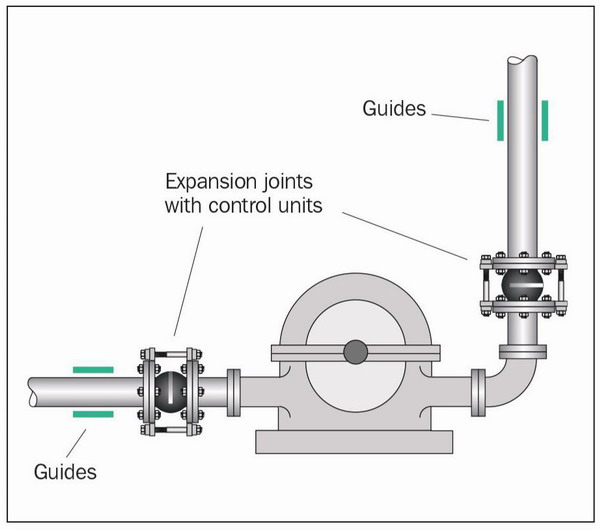

The expansion joints shall be easily accessible and open to regular supervision. Lt is recommended to let the expansion joints work in compression rather than stretching. Torsion is not permitted.Maintenance instructions: observe whether the rubber joint is overstretched and keep the rubber joint at normal length every month.Pressure-restrained expansion joint on the pump (with tie bar).

The expansion joints shall be easily accessible and open to regular supervision. Lt is recommended to let the expansion joints work in compression rather than stretching. Torsion is not permitted.Maintenance instructions: observe whether the rubber joint is overstretched and keep the rubber joint at normal length every month.Pressure-restrained expansion joint on the pump (with tie bar). Absorb vibrations and thus relieve pressure on the machine housing.

Absorb vibrations and thus relieve pressure on the machine housing. Arrangement with lateral expansion joints.

Arrangement with lateral expansion joints.

Mounting

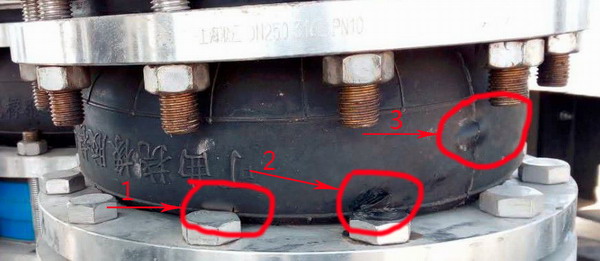

MountingIf this is for any reason impossible, ensure that the threaded bolts project as little as possible(no more than 2 or 3mm)to avoid damage to the body.

Tightening must be progressive and crosswise in diagonal sequence with bolting pressure evenly distributed.

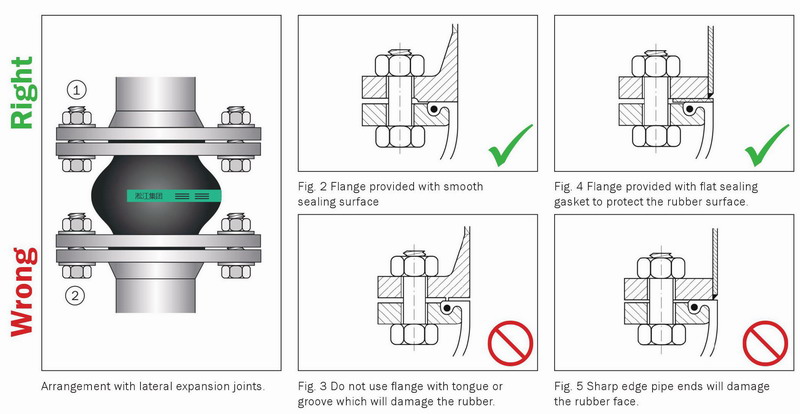

The design of the expansion joints secures a sealing to the counter flange. That is why no sealing gasket is required.

Note: If the bolts and nuts are tightened too strongly, the sealing face might be crushed causing function!

Counter flanges

The safe operating and life expectancy of the expansion joint needs to make a proper installation of the counter flanges(Fig. 2 to 5). The sealing face of the counter flange must be machined smooth and cover most of the rubber sealing face(or at least 60%)to ensure good sealing(Fig.2).

Precaution

Do not paint or lubricate rubber parts of expansion joints!

When welding work is to take place the bellow has to be protected from welding heat and sparks!

Attention: Please strictly use the rubber fittings of the union according to the above requirements, if not used, cause any consequence, be not responsible for.

Related links: Rubber expansion bellow product center From High-quality Rubber Expansion Bellow Manufacturer